Building A One-of-a-Kind Automobile

Designer Jim Simpson, in his own words

The first step in creating a custom sportscar begins with the design goals. After extensive discussion with the client—getting a sense for their tastes and what they want in their finished car—I will determine the sort of running gear around which the car will be built. This determines the scale and we can see if the project will be suited to being built using an existing car's platform. Building on an existing platform is often an ideal situation, offering the best middle ground between performance, customization and ease of maintenance for the client after my work is complete.

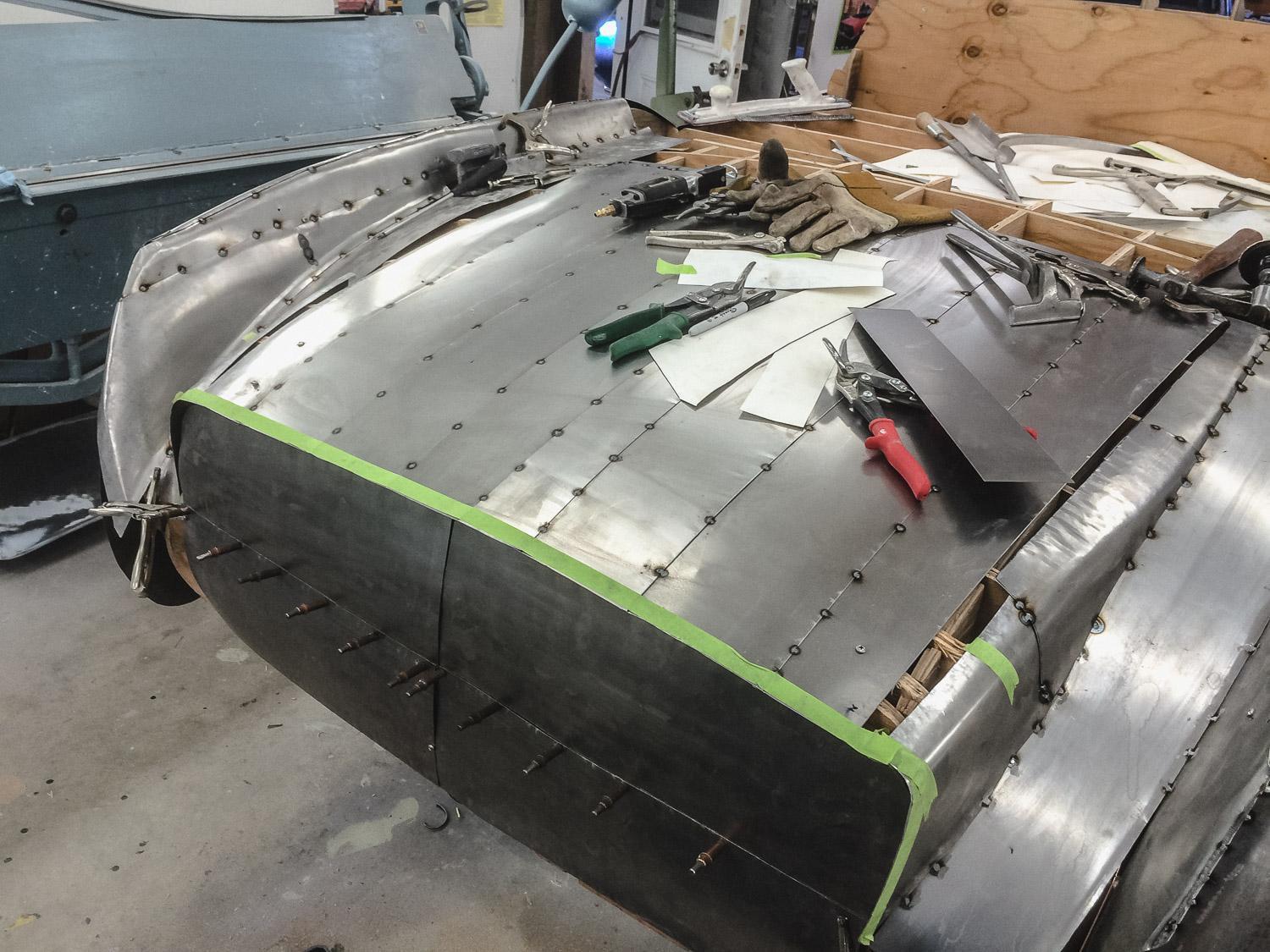

Jim creating a paper template for a metal part to be hand-shaped out of steel.

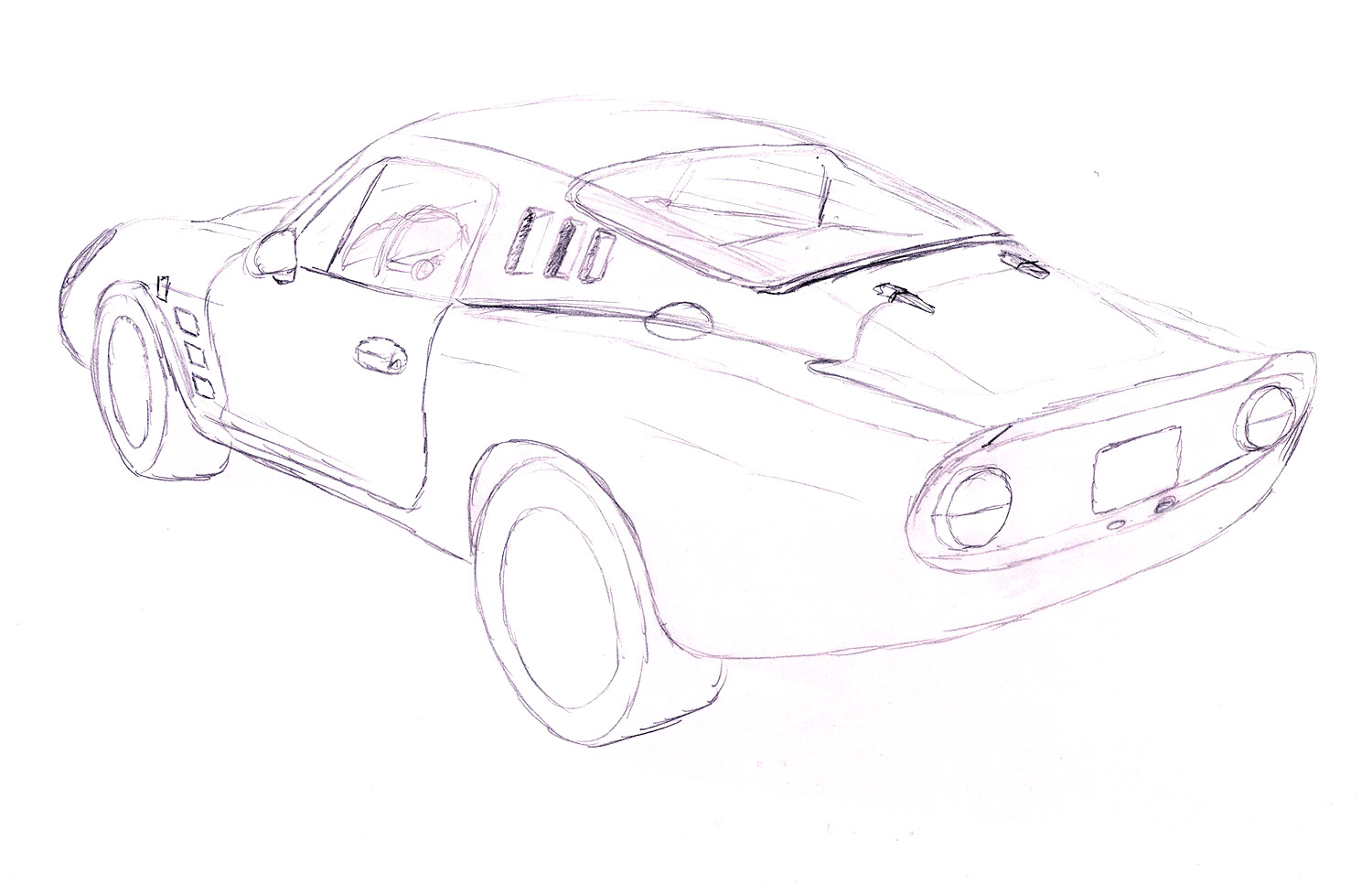

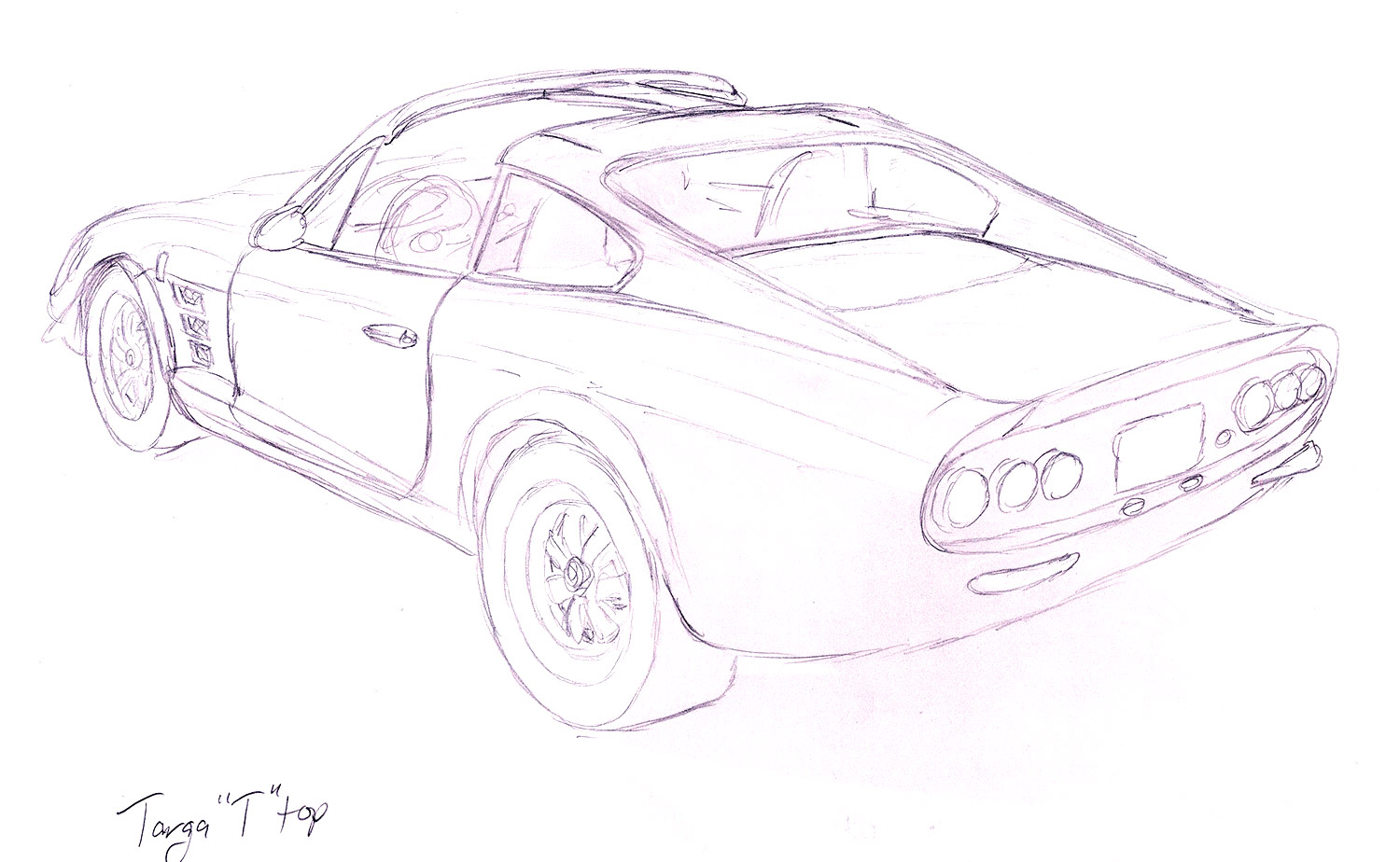

The process itself begins with rough sketches, studying those sketches and making minor alterations. Designers who work primarily in 2D sketches can fall into the trap of drawing things that are not possible to build in 3D. This is why I typically scratch-build a 1/24 scale resin model based on my initial sketches to see the viability of shapes in a tangible 3D mockup.

Sculpting at Scale

The modelmaking process typically takes several days spent studying and sculpting the shape, drawing on the in-process model with a pencil to highlight details or explore ideas. As the design direction becomes clearer, I start to cut hood and door lines as well as glass silhouettes into the model, then carefully sand, prime and paint the model using real automotive urethane paint. At this stage, it's perfect for showing off the design to a client as a very realistic representation of what they'll be getting, or for getting the feedback of other automotive designers I correspond with. A well-proportioned scale model can be photographed from the same angles as a finished car to make visualizing the final product much easier.

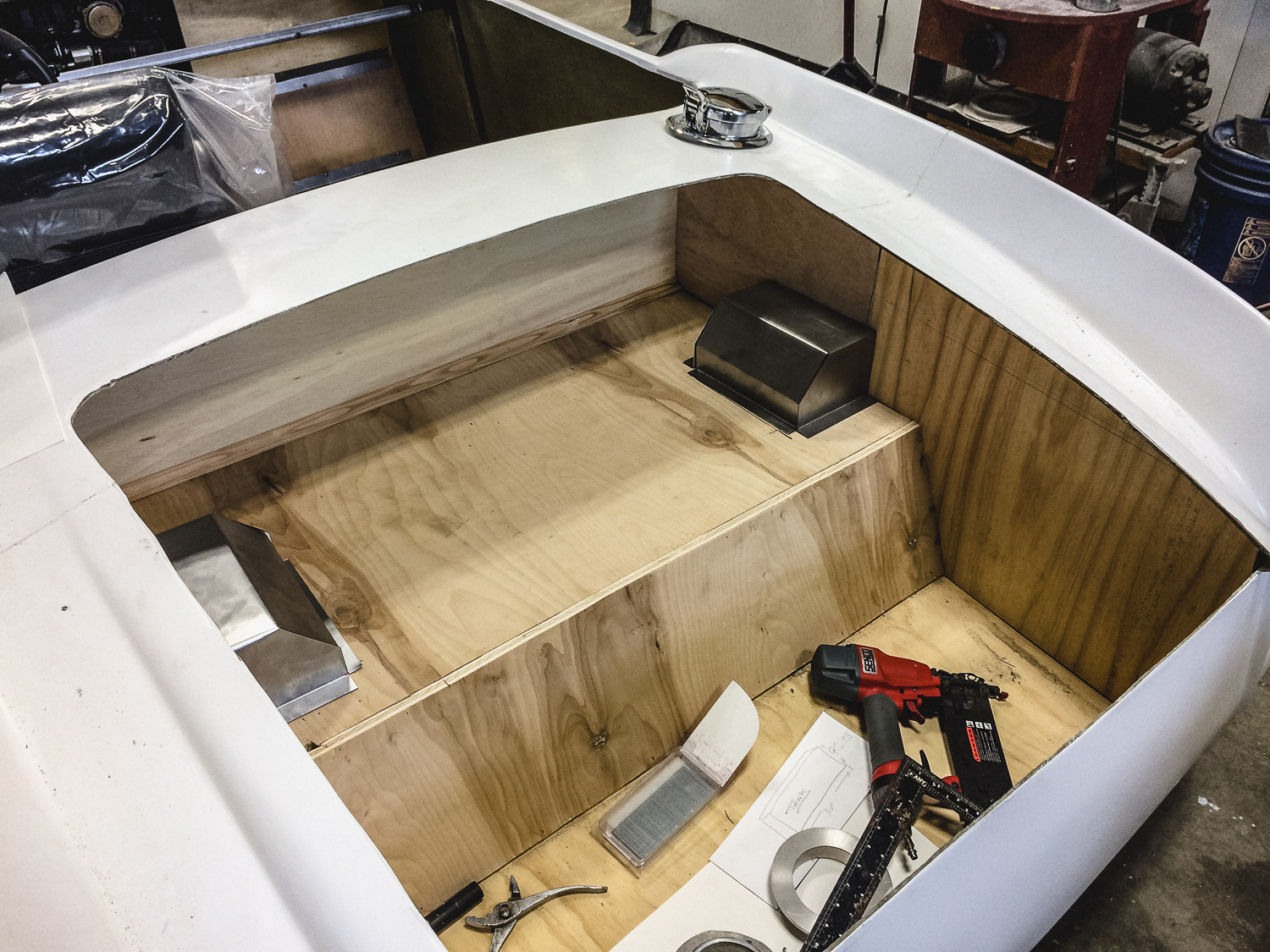

Buck and Steel

Once a good quality donor car for the base platform and mechanicals has been acquired, I strip it of the vast majority of the stock parts and body panels, creating what will be the blank canvas. I start by creating a guideline "buck," typically made of wood,over which I hand-shape the body form in steel.

Plug and Fiberglass

I refine the shape further in steel and primer until I have something that I would deem production ready. At this point I send the plug—the 'master copy' of the body—to the fiberglass shop that produces our moulds and parts. The initial steel shaping for the plug is the most time-intensive part of the process—once fiberglass parts are produced from the moulds, the body of the finished car goes together relatively quickly.

Interior and Trim

Every interior we make is different, depending on what an individual client requests. We work to be conscious of comfort as well as budget- making efficient choices that balance the style of the finished car and the owner's taste. The materials for any interior are carefully chosen to impact all of the senses- the feel of the seat, the smell of fine leather, the gleaming finish of the handmade steering wheel. In the end, the interior is the most intimate part of a driver's experience of their car.

Final assembly and Paint

Possibly the most exciting part of the process is the final assembly. The car is fully detailed after the finished body panels are fitted- door handles, mirrors, custom knockoff wheels and all other accessories are incorporated into the car at this stage. While we have painted some cars in-house, we also collaborate with highly skilled painters and paint shops in the area to produce a truly show-ready level of finish for our clients. While many owners prefer a simple, refined single-colour paint job, we're always excited to devise racing stripes and other flashier treatments depending on what a client desires.

Production Cars

For our limited production cars- non one-offs- this is also a chance to find any small mistakes in production so the final product can be refined and reproduced accurately across the whole run. The Italia 2 is a prime example of this. When building a oneoff, you can often live with compromises and making more adventurous or strange shapes that would be difficult to reproduce more than once, but a production run needs to be production-minded.

If you're interested to see more of the behind-the-scenes process at Simpson Design, Jim posts frequently on our Facebook page with updates on his current projects, be they cars or model-making. He's always happy to answer questions about design or his process.